My new book on modeling historical aircraft is already available in the web shops. This is the second volume of the new (fourth) edition of the “Virtual Airplane” guide:

Continue reading New Guide about Modeling Historical Aircraft

My new book on modeling historical aircraft is already available in the web shops. This is the second volume of the new (fourth) edition of the “Virtual Airplane” guide:

Continue reading New Guide about Modeling Historical Aircraft

In this post I will complete the 3D reference that I started in the previous post. Here is a link to the Blender file that contains 3D reference skeleton of the “long nose” P-40, described in the text below. It was compiled from all available blueprints.

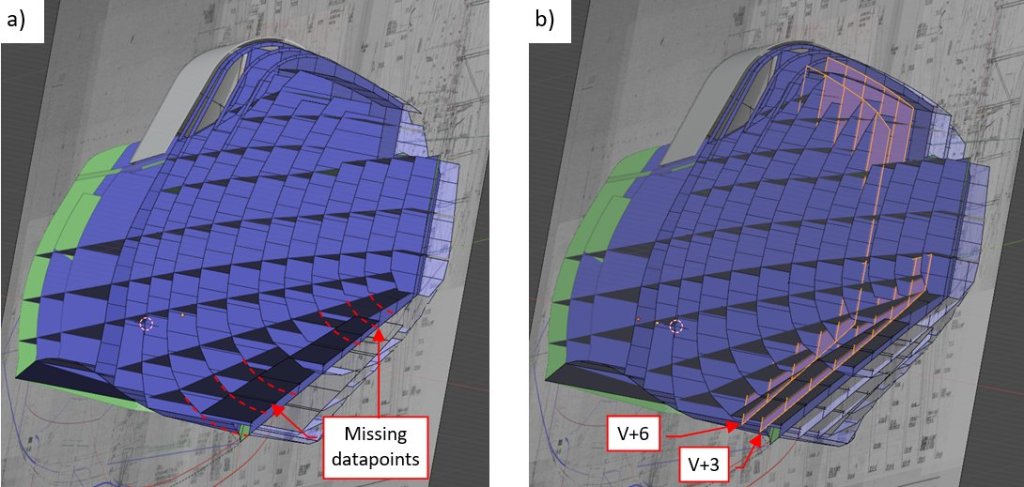

Studying the dimmed blueprint scans, I was not able to read some horizontal ordinates placed close to the top and bottom segments of this fuselage. This created gaps in my 3D grid (Figure 121‑1a):

Fortunately, in the fuselage ordinates diagram (dwg 75-21-020) I was able to identify ordinates of two vertical planes, placed at +3” and +6” from the symmetry plane (Figure 121‑1b). This allowed me to interpolate these datapoints with curves.

Continue reading Recreating the P-40B: 3D Reference of the Fuselage (2)

At this moment I am working on second volume of my book about 3D modeling. It describes building a 3D model of a WW2 aircraft on the example of the P-40B. Preparing for this work, I discovered that the original documentation of this early P-40 variant (also known as “long nose Warhawks”) is missing. On the other hand – you can find plenty of the “short nose Warhawk” blueprints (related to the P-40D later variants), as well as some P-36 drawings. I started by picking over 1000 original Curtiss blueprints and sketches related to the P-40, XP-40, and the P-36 from the vast resources of the AirCorps Library. Then I analyzed their contents, comparing them to the available historical photos. I described this process in this and following posts, written in 2019. Ultimately I traced side view of the P-40B. I also concluded that a 3D visualization of the available ordinals will be a better reference. In the previous posts I built such a reference for the SBD Dauntless. In this and the next post will I describe similar work on the fuselage of the early P-40 variants (P-40-cu, P-40B, P-40C).

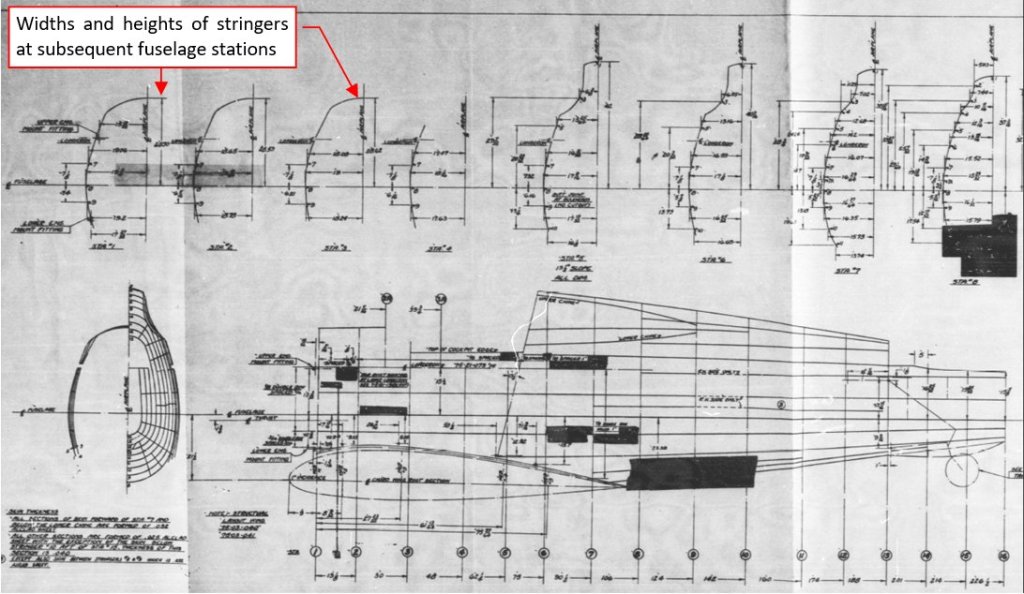

I prepared an empty Blender file. For the convenience, I placed there my side view (from this post, see Figure 102-15). As for the SBD model, I assumed that 1 Blender unit = 1 in. For the main part of this fuselage, spanning from the firewall to the rudder, I used two P-36 diagrams. First of them (dwg 75-21-140) provides locations of the fuselage stiffeners at each bulkhead. There is also its modified variant (dwg 75-21-836) for the XP-40:

Continue reading Recreating the P-40B: 3D Reference of the Fuselage (1)

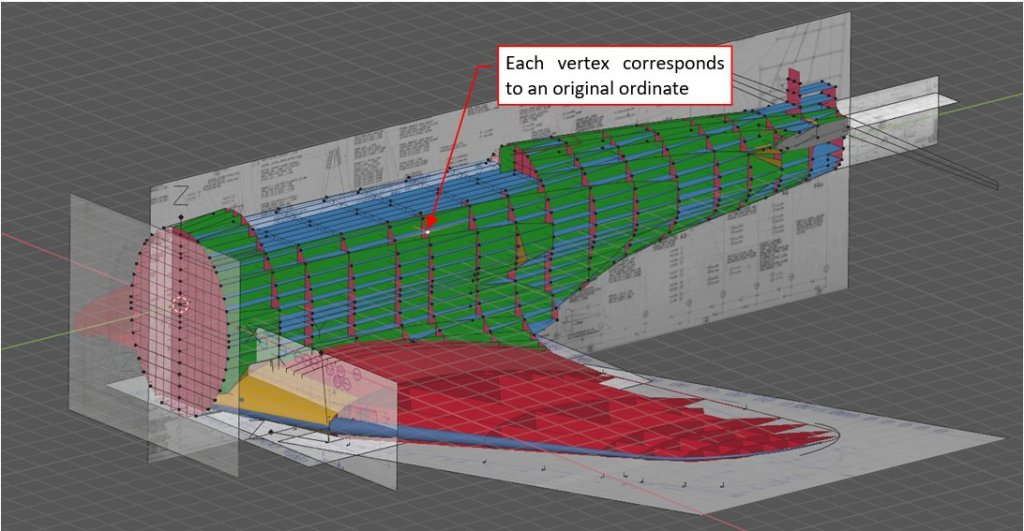

I decided to upload the Blender file in which I reproduced in the 3D space the original ordinates of the SBD fuselage and wing. (I described creation of this 3D reference in my previous posts). I think that in this form they can be useful for other modelers, who would like to recreate the geometry of this aircraft. Here is the link to the *.blend file (102MB) that contains the model presented below:

Continue reading Original SBD Dauntless Blueprints: Ordinates

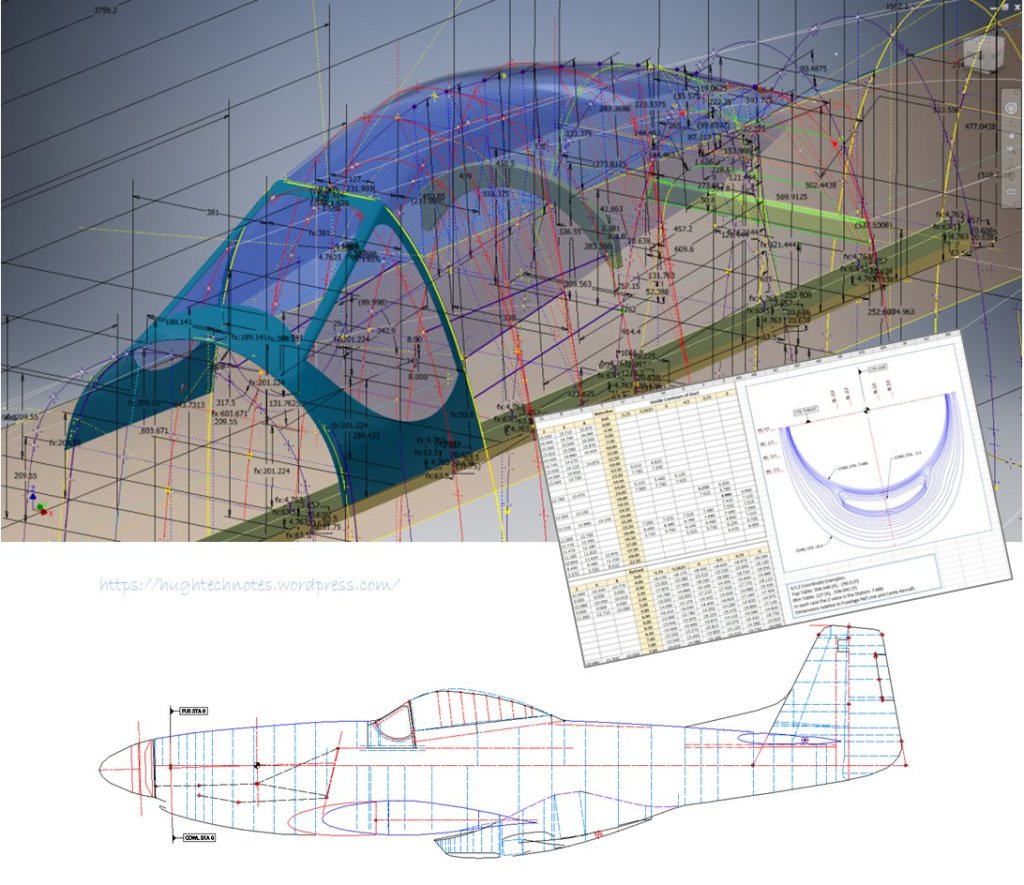

For over ten years Hugh Thomson has published marvelous posts in his blog about the historical aircraft. Just look there to see the P-51 Mustang, F6F Hellcat, F4F Wildcat and B-25 Mitchell CAD models and – what is sometimes even more important – compiled datasheets of their ordinates. The true, accurate geometrical data are usually dispersed and difficult to reconcile in the thousand sheets of the faded out, barely readable original blueprints. Hugh studied them all and is providing this information in the easy-to-use form. If you need such data on any of these aircraft – visit his page and choose any of these packages, or just make there a donation, to support his future projects!

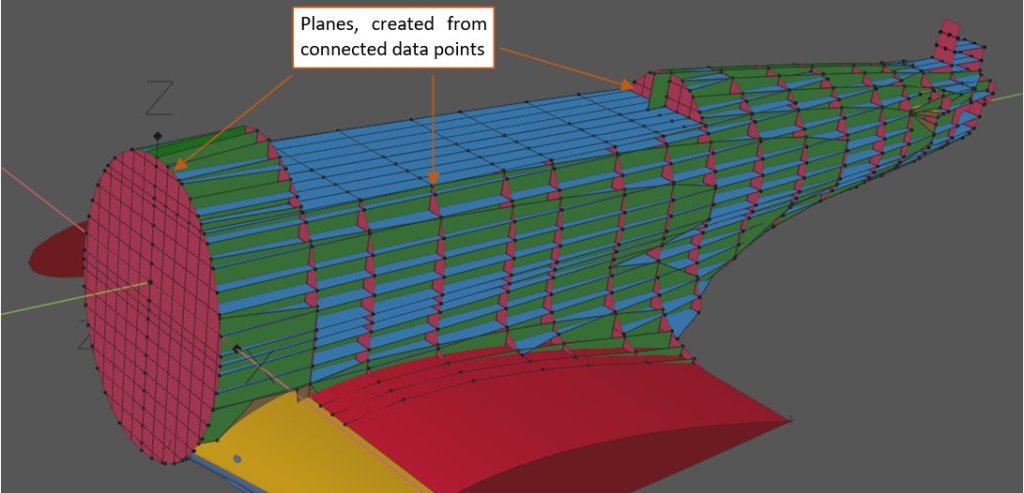

In the previous post I used ordinals from the newly found fuselage geometry diagram for creating a set of the 3D reference planes:

In this post I will span a smooth subdivision surface between these points. I think that such an interpolation will provide a more accurate reference than the longerons (stiffeners), which I previously shaped in this post (see there Figure 112-07).

Continue reading Original SBD Dauntless Blueprints: Fuselage Geometry (4)

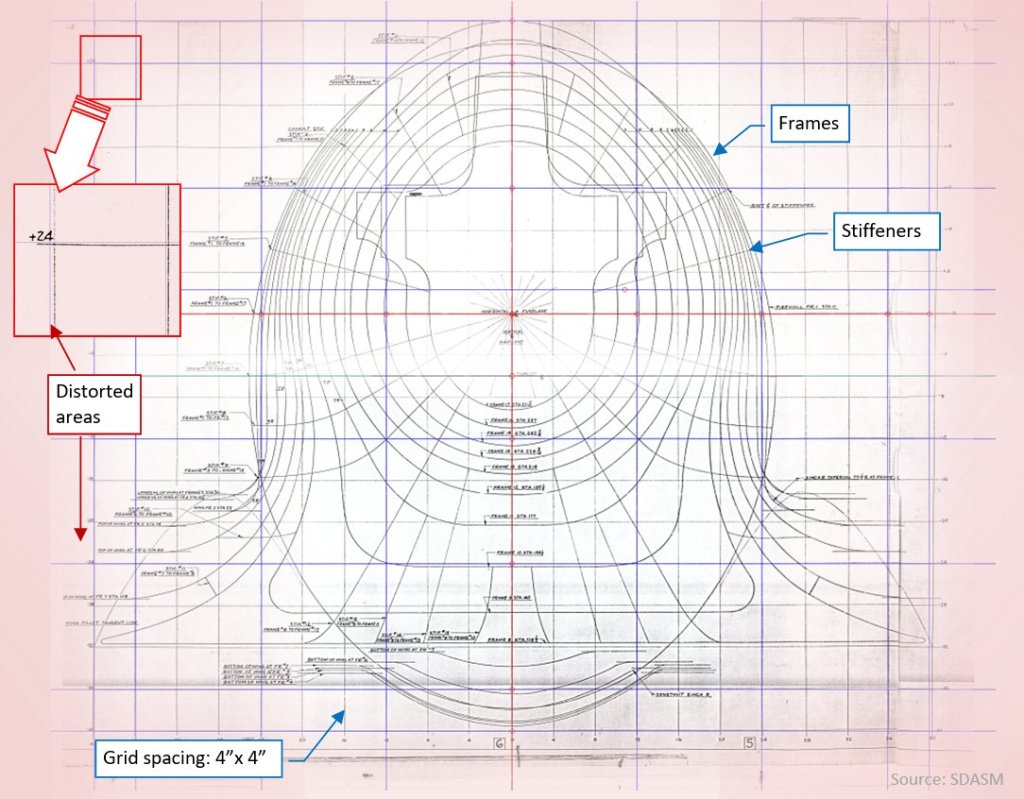

This February I found among the SDASM resources a diagram (dwg no 5060837), which describes the geometry of the SBD fuselage. This is the key piece of the information that was missing in the NASM microfilms I used before. Below you can see these lines:

Continue reading Original SBD Dauntless Blueprints: Fuselage Geometry (3)

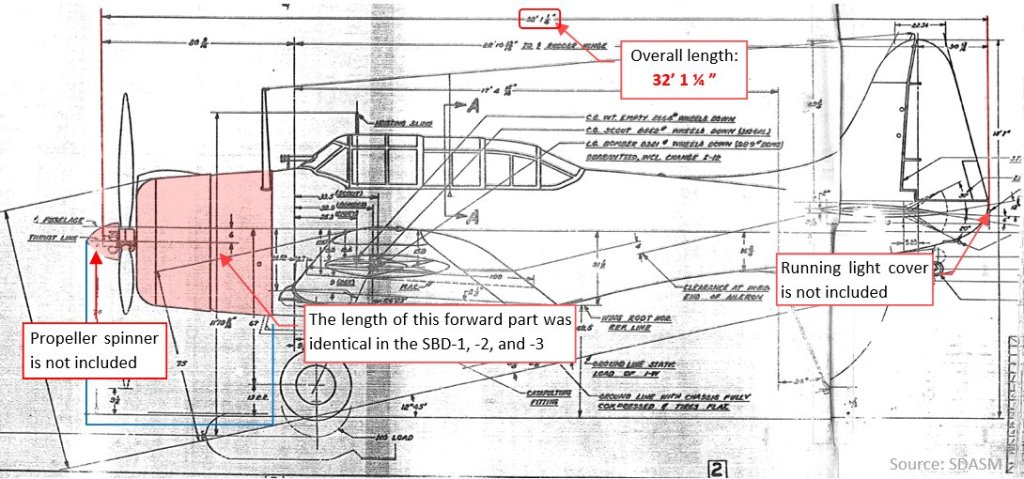

Since 2015 I have tried to determine the true length of the early SBD Dauntless versions (the SBD-1, -2, and -3). There was something wrong with the source of this information: the original BuAer performance data sheets. You can find there different lengths of the SBD-2 (32’ 2”) and the SBD-3 (32’ 8”), while the differences between these variants cannot explain the reason of such a longer fuselage in the SBD-3. The other sources repeat these figures without any reflection. Fortunately, last month I found in the SDASM resources two interesting drawings of the SBD-1. One of them is a general arrangement diagram, which clearly specifies its overall length (and how it was measured):

Continue reading The Overall Lengths of the Douglas SBD Variants

My new book on preparing aircraft reference drawings is already available in the web shops. This is the first volume of the new (fourth) edition of the “Virtual Airplane” guide:

Continue reading The Book about Aircraft Reference Drawings Is Available

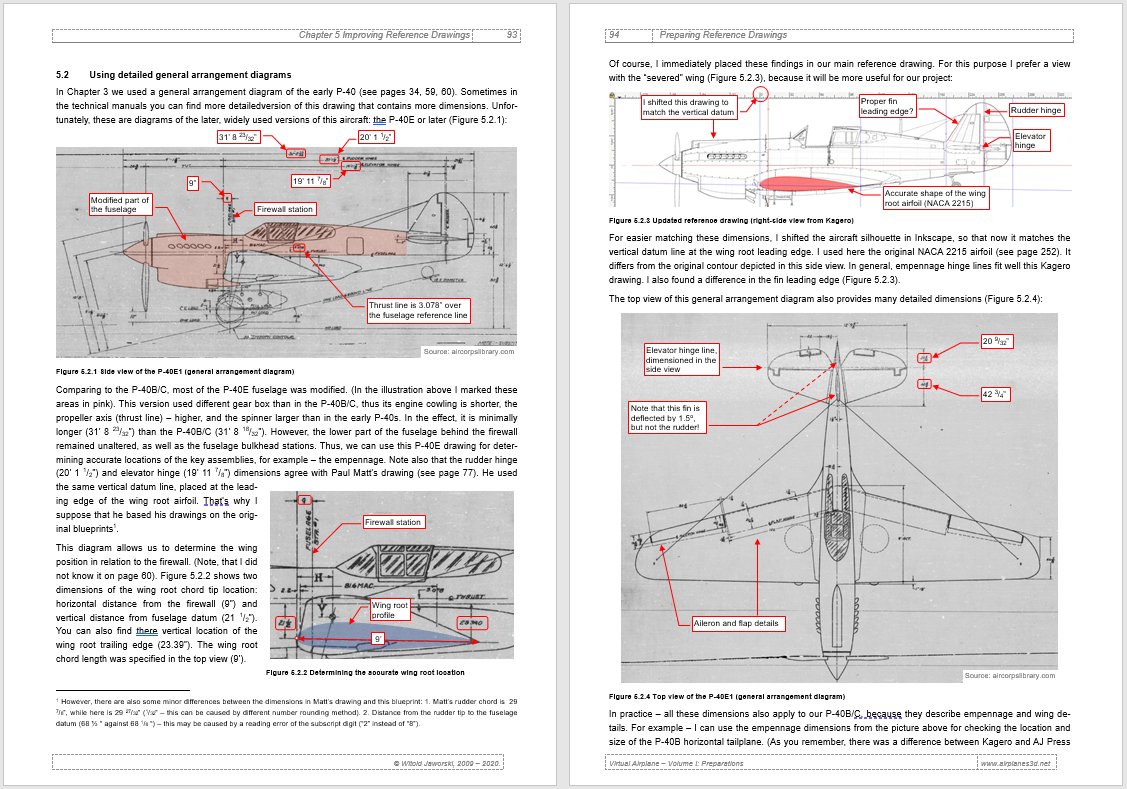

This June I started working on a new (fourth) edition of my book about aircraft computer models. Actually, I am finishing its first volume (“Preparations”). It describes how to prepare accurate reference drawings of a historical airplane, on the example of the P-40. Below you can see two of its pages (as they appear my screen):

Comparing to the third edition, I altered here the proposed workflow, using Inkscape as my basic tool. I also wrote more about eventual errors, which you can find in typical scale plans. In the appendices I included a section about the original P-40 blueprints, which is based on the posts from this blog. Here is the link to the excerpt from this publication. It contains the table of contents. I expect to release this book in January 2021. (I will write a post, when it will be available).