At this moment I am working on second volume of my book about 3D modeling. It describes building a 3D model of a WW2 aircraft on the example of the P-40B. Preparing for this work, I discovered that the original documentation of this early P-40 variant (also known as “long nose Warhawks”) is missing. On the other hand – you can find plenty of the “short nose Warhawk” blueprints (related to the P-40D later variants), as well as some P-36 drawings. I started by picking over 1000 original Curtiss blueprints and sketches related to the P-40, XP-40, and the P-36 from the vast resources of the AirCorps Library. Then I analyzed their contents, comparing them to the available historical photos. I described this process in this and following posts, written in 2019. Ultimately I traced side view of the P-40B. I also concluded that a 3D visualization of the available ordinals will be a better reference. In the previous posts I built such a reference for the SBD Dauntless. In this and the next post will I describe similar work on the fuselage of the early P-40 variants (P-40-cu, P-40B, P-40C).

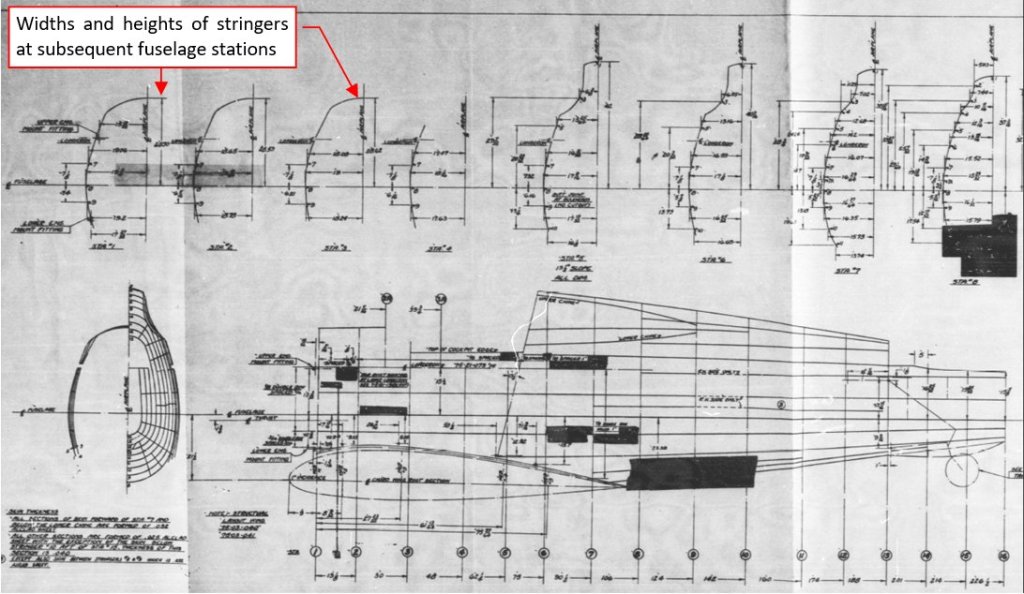

I prepared an empty Blender file. For the convenience, I placed there my side view (from this post, see Figure 102-15). As for the SBD model, I assumed that 1 Blender unit = 1 in. For the main part of this fuselage, spanning from the firewall to the rudder, I used two P-36 diagrams. First of them (dwg 75-21-140) provides locations of the fuselage stiffeners at each bulkhead. There is also its modified variant (dwg 75-21-836) for the XP-40:

Continue reading Recreating the P-40B: 3D Reference of the Fuselage (1)