As I already mentioned in this post, my microfilm set does not contain the fuselage geometry diagram. (I suppose that it was included in the missing roll C). Thus, this part of my work will be much more difficult, because I even do not have complete set of the bulkhead drawings! Just found a structure assembly drawing (i.e. side and vertical views), skin panels assembly drawing, mid-fuselage bulkheads, and some bulkheads of the tail. In the picture below I marked these undocumented areas of the fuselage in transparent red:

Douglas blueprints refer to the fuselage bulkheads as “frames”. They are numbered from 1 (the firewall) to 17 (the mounting base for the tail wheel and horizontal stabilizer). Of course, the fuselage assembly drawings provide their positions, measured from the firewall. (You can find them in this assembly drawing of the skin panels). In this post I will refer to fuselage bulkheads using their ordinal numbers, shown in the picture above (for example: “frame #05”).

However, even the identified blueprints of the fuselage frames are usually assembly drawings, which means that they do not contain any useful dimensions (as the frame #05 in Figure 112‑2a):

All you can do witch such a drawing is to use it as a reference image. This is not the best option, because these microfilm pictures are always slightly deformed, due to paper folds and distortion of the camera lens. In the case of detail drawings you can find some useful dimensions, like the overall fuselage width (measured from the center plane), or the height. (As in drawings of frame #07 in Figure 112‑2b,c). Note that these frames are split along the fuselage reference plane into the upper and lower part. While the upper part (Figure 112‑2b) at least resembles a bulkhead, in the case of the lower part (Figure 112‑2c) I had to think for a while before determining its inner and outer side.

Because I have only a few vertical photos of the fuselage, one of the most important information are bulkhead widths. I have collected them just for the 7 frames:

Except frame #03, these fuselage width are measured at the reference plane (longeron #06). In the case of the firewall, this is not the point of the maximum width. (Firewall has an elliptic shape, which origin lies 6” lower, on the propeller thrust line – see Figure 112‑4). Note that I also found two widths of the cockpit frame. These two points, combined with the height from Figure 112‑2b), allowed me to determine precise location of this very important longeron. (It forms a base for many other dimensions). Unfortunately, I did not find explicit width dimension for the last frame (#17).

I also verified the fuselage blueprint from Figure 112‑3, checking its symmetry. Unfortunately, I found that this contour is asymmetric (i.e. the drawing is deformed) in the area without dimensions (between frames #8 and #11). This deformation could occur during microfilm production. (This blueprint was originally split between four film frames, and frame 3 and 4 overlap in this area). However, these drawings were manually traced in ink, and this can also be a human (draftsman) error.

If you wonder about the error range of the lines traced on the original blueprints, look at the picture below. It shows two drawings of the firewall. One of them is in red, while the other in black:

As you can see, contours of these two firewall “instances” can vary even by 0.3” (0.4% of the overall size). Which one is closer to the real contour? I decided that I will use the red drawing, because it is symmetric, and its contour mostly agrees with the left side of the black blueprint. I suppose that at least part of these differences are non-critical draughtsman errors.

The most important elements of the technical drawings are their explicit dimensions. Depicted object has just to resemble the real thing, making the drawing readable. All curves are described by datapoints (ordinals), grouped in the geometry diagrams. That’s why for a manufacturer/workshop both of the compared firewall assembly drawings are valid, in spite of these differences.

Unfortunately, without the fuselage geometry diagram I have to rely on these “not-so-precise” object contours. This means that in my “3D reference frame” that I am building in Blender the possible error range will be much wider in the fuselage than in the wing. (Because the wing reference objects were mostly based on the original geometry diagram). In the second part of this post I will try to improve this situation a little, checking some doubtful/undocumented areas with the reference photos.

I placed the identified drawings of the fuselage frames in the 3D space, using some of their largest horizontal and vertical dimensions for determining the proper scaling. However, in the effect there were so many overlapping half-transparent pictures (as in Figure 112‑5a) that in the practice the whole thing could not be used as a reference. It forced me to recreate each frame as a 3D planar contour, and hide their source drawings:

For the beginning, I focused on the better documented mid-fuselage. Once the bulkheads were created, I connected them with the cockpit frame and other longerons:

The longest longeron #06 lies on the fuselage reference plane, thus its shape from frame #05 to frame #17 determines the fuselage contour in the top view. For the convenience, these longerons run along the original longeron lines, depicted in the fuselage assembly drawing.

These longerons helped me to find and fix minor differences in the shape between subsequent bulkheads:

(When you look along the longeron at high angle, as in the picture above, you can quickly find all differences in the local width of the subsequent bulkheads.)

That was the easier part. Now I have to recreate the tail bulkheads. As you can see in Figure 112‑1, I found only the upper parts of frames #13..#16, and complete closing frame (#17). They contain just a few usable dimensions. Paraphrasing well-known Goya’s title, “the lack of dimensions produces assumptions”, and assumptions are the main source of eventual errors. However, there is no other way. In this case I have to make several assumptions about the shape of tail bulkheads.

Of course, first I reviewed all the blueprints for any hint about their shape. I have found some fragmented contours of tail bulkheads placed as additional information in other drawings. For example – figure below shows all what I found about frame #09:

The continuous red line marks the frame #09 contour, identified in two drawings. The left picture comes from cockpit enclosure assembly drawing, while the right picture is a fragment of an internal diaphragm assembly. The drawing of the cockpit enclosure (left) contains upper part of frame #09 contour. It looks as it was formed from an arc and straight segments (this is my first assumption). In the diaphragm assembly (right) you can see a complete frame #09 contour, up to the reference plane. It seems to be formed by a 3 arcs and a straight segment (this is my another assumption).

Design of this fuselage tail comes from the historical Northrop Gamma/A-17 aircraft line. First Gamma was built in 1932. In that time aircraft designers seldom incorporated advanced curves in their shapes, because they were much more difficult to recreate in the workshop than ordinary arcs. That’s why I stick to identifying circular sections in these contours.

I placed these two images in the 3D space, then created auxiliary circles fitting the assumed arcs. Using their contours, I created the model of frame #09:

As you can see, there is still a completely undocumented segment above the fuselage reference line. I based its shape on the corresponding segment in the last documented frame (#07).

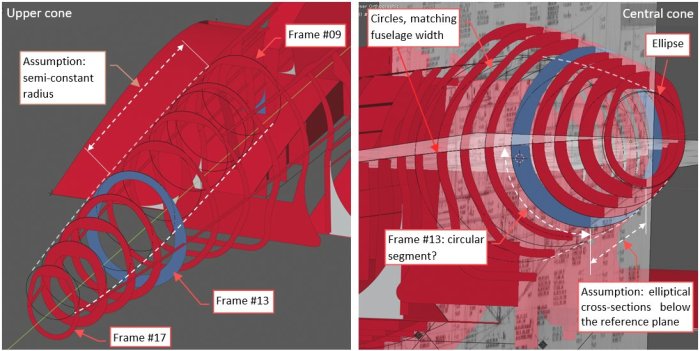

I could identify similar arcs in the tail bulkheads. They fitted the available drawings of frame #13, #14, and #15. To ensure smooth shape transition between subsequent bulkhead contours, I organized these auxiliary circles into “cones”. Below you can see pictures of the first two cones, which form the main part of the tail:

For easier recognition, I marked the first documented tail frame (#13) in blue. Its width and height are determined by explicit dimensions, while the shape of previous frames is based mainly on assumptions. In picture above, left, you can see the upper cone. It starts with the frame #09 contour, which should fit the cockpit enclosure (arc diameter: 22.5”). Then it remains nearly constant up to the frame #13. (In fact, it seems to slightly enlarge its diameter, reaching maximum – 24” – at frame #13, then quickly decreasing in the further frames. For frames #16 and #17 this contour is meaningless, because their upper parts are completely hidden inside the horizontal stabilizer fairing).

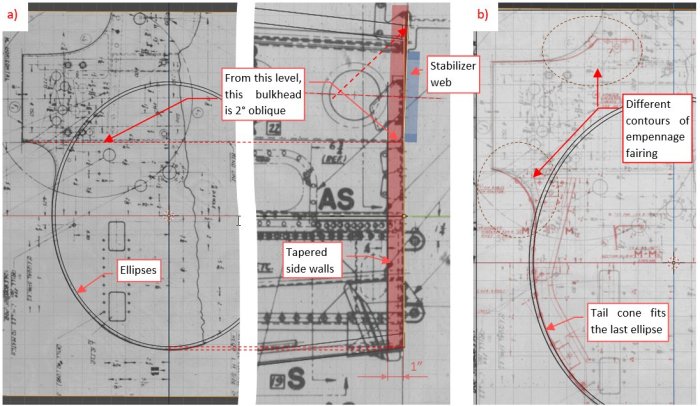

In the picture above, right, you can see the central cone. Its axis lies on the fuselage reference axis, and its side contour is the side contour of the fuselage. I did not find any drawings of the lower part of frame #13. Basing on the side and top fuselage contours I decided that it was a simple circular segment, precisely matching the central cone. I assumed that the lower contours of all further frames (#14, #15, #16, and #17) were elliptical, because frame #17 seems to fit into an ellipse (as you can see in Figure 112‑11a):

This frame had relatively large, tapered side walls (1” wide), thus I placed in this drawing two ellipses: one for the inner, and one for outer contour (both marked in the source blueprint). As you can see, these contours fit them pretty well. Note also that the upper part of this bulkhead is 2° oblique, to fit the attached rear stabilizer spar (web).

I also verified this elliptical contour in another drawing, of the first bulkhead in removable tail cone section (you can see it in Figure 112‑11b, marked in red). The last ellipse fits both blueprints. However, I noted differences between these drawings in the empennage fillet shape. (Compare its black and red contours in the marked areas of Figure 112‑11b).

In the next post I will continue my work over the lower part of the fuselage. I still have to prepare references for the large wing fillet, which spanned along half of the SBD fuselage length.

Admire your tenacity at developing this model! It’s been a long time.

LikeLike

Thank you! Frankly speaking, I did not expect that it will take me so much time, but I made a long road since the start, finally reaching the unpublished, original blueprints – only to discover that they are also incomplete. There is still a chance that at the end of this “pursuit” I will buy one of the survived SBDs from a museum :).

Anyway, this is one of the few projects that I am running. The another one is the new edition of the “Virtual Airplane” guide. I started working on it this May, and I expect to publish the first volume (about the scale plans and reference drawings) at the end of this year. It will be mostly rewritten. I am going to modify the described workflow, and add many materials which I already shown in this blog.

LikeLiked by 1 person

great job,the best on the web I can’t wait for the next post to visualize the process of the lower fuselage and drawings, to start the my work of the SBD DAUNTLESS cockpit in 3d,

these are Some of my nidest jobs :

https://grabcad.com/josep.calvo-1/models

LikeLiked by 1 person

Thank you,

and congratulations for your models!

What program do you use?

LikeLiked by 1 person

Thank you

solidworks 2018 for modeling and Keyshot9 for render

LikeLiked by 1 person